Help modifying concrete building to make a cold smoker

Hi Travis,

It's very important to make it vermin proof, especially around door frames, doors, floors and smoke entry as well as air vents.

Many years ago I have seen salamis being consumed by hungry mice and bush rats.

They ate the tops of every salami.

The solution was to hang the salamis or sausage to be smoked on approx. 16" long pieces of 1/16"welding wire. No string at all as these rodents have plenty of grip on string.

Good luck,

Jan.

It's very important to make it vermin proof, especially around door frames, doors, floors and smoke entry as well as air vents.

Many years ago I have seen salamis being consumed by hungry mice and bush rats.

They ate the tops of every salami.

The solution was to hang the salamis or sausage to be smoked on approx. 16" long pieces of 1/16"welding wire. No string at all as these rodents have plenty of grip on string.

Good luck,

Jan.

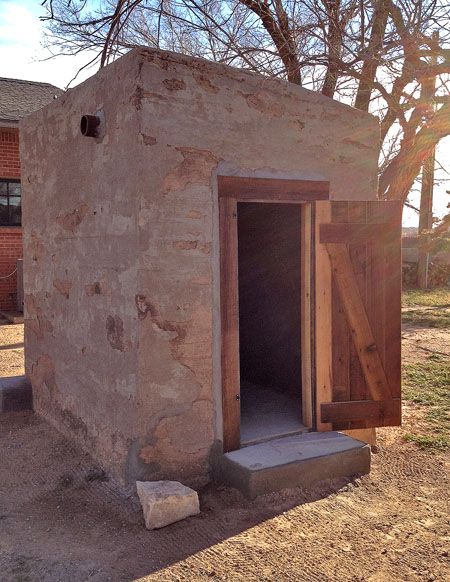

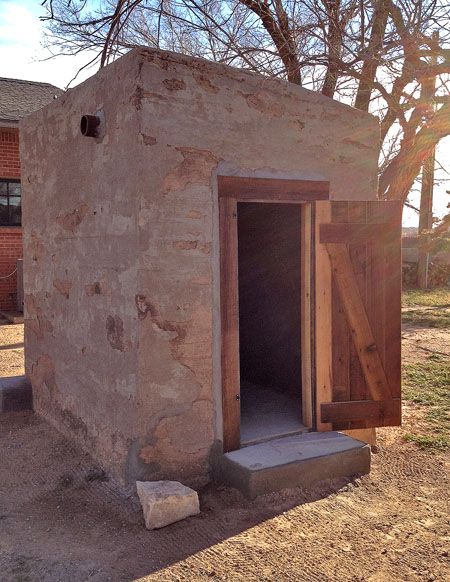

Well it has continued to be slow going but I think I'm on the home stretch. I got the door built and it all seals up good.

I lost lots of sleep worrying about boring through that cement to get my smoke inlet and vent but a solid morning with a hammer drill then hammer and cold chisel and I had it whipped.

I built two of these out of 1/4" plate and 5" casing to go through the walls. I anchored them with concrete screws and mudded them in.

The above spot is where the fire box is going.

Upper left in the below photo is where I am putting my vent which will have a rain cap and a damper.

This is where the smoke will come in. Also got the re-finishing job complete on the walls...it was the most tedious and time consuming part of this project thus far.

I'm about through with my fire box...it's 28" long and made from 20" casing set horizontally.

Regarding racks for meat etc.....I'm planning on building two simple supports on either side of the house out of lumber and just suspend rods in between them. My only issue is what to use for rods. The only wooden dowel rods I can get locally aren't very long...4' max. Any ideas on this one?

I lost lots of sleep worrying about boring through that cement to get my smoke inlet and vent but a solid morning with a hammer drill then hammer and cold chisel and I had it whipped.

I built two of these out of 1/4" plate and 5" casing to go through the walls. I anchored them with concrete screws and mudded them in.

The above spot is where the fire box is going.

Upper left in the below photo is where I am putting my vent which will have a rain cap and a damper.

This is where the smoke will come in. Also got the re-finishing job complete on the walls...it was the most tedious and time consuming part of this project thus far.

I'm about through with my fire box...it's 28" long and made from 20" casing set horizontally.

Regarding racks for meat etc.....I'm planning on building two simple supports on either side of the house out of lumber and just suspend rods in between them. My only issue is what to use for rods. The only wooden dowel rods I can get locally aren't very long...4' max. Any ideas on this one?

- Butterbean

- Moderator

- Posts:1955

- Joined:Mon Mar 05, 2012 04:10

- Location:South Georgia

Re: Help modifying concrete building to make a cold smoker

Travis, that is a beautiful project. I am by no means an expert on this type stuff but I just finished one and learned a few things you might find helpful. For the cold smoke, if you will back your firebox away from the house about 7 feet and use pipe and elbow it into the ground then elbow up again this will cause friction and reduce your draft which will keep your fire from burning so hot and insure cold smoke. This cold smoke will waft into the house and a fan isn't really necessary.tdimler wrote: I would likely add a small fan inside to circulate the air/smoke since it would be coming in at an odd spot. Additionally, to keep from boring a hole in the concrete ceiling for a vent, would it work to construct an adjustable vent in the door?

I am open any ideas/suggestions....

Travis

Here is a pic of the cold smoke coming from my fire box. It almost looks like dry ice vapor and it just lays in the house and fills up with a gently draft.

Personally, I was quite pissed at how mine worked at first till I realized how the thing was working to my benefit. I got some good advice here on the board and I'm really please with how its now working.

My firebox is about the same size as yours and with such little draft you will be amazed at how long the box will lay smoke on the food with one filling.

For hot smoking I had to add a supplemental burner on the inside. This works great for drying the sausage to form the pellicle and then I fire up the smoke box and it will last a day.

Beautiful smokehouse.

Re: Help modifying concrete building to make a cold smoker

I read through your thread yesterday and was going to comment but didn't get to it. We've got a pretty similar situation. Shouldn't be a problem to back the fire up and get a cool smoke. I'm really hoping I can shoot straight from the fire box into the smoker and see how hot I can get it in there. It will likely be 18"-24" from the fire box into the house. I'd like to be able to supply enough heat to at least finish sausage. I can build a stonking big fire in my box but just not sure how much heat I can get into the house. Don't guess I'll know until I try it!Butterbean wrote:

Travis, that is a beautiful project. I am by no means an expert on this type stuff but I just finished one and learned a few things you might find helpful. For the cold smoke, if you will back your firebox away from the house about 7 feet and use pipe and elbow it into the ground then elbow up again this will cause friction and reduce your draft which will keep your fire from burning so hot and insure cold smoke. This cold smoke will waft into the house and a fan isn't really necessary.

Personally, I was quite pissed at how mine worked at first till I realized how the thing was working to my benefit. I got some good advice here on the board and I'm really please with how its now working.

My firebox is about the same size as yours and with such little draft you will be amazed at how long the box will lay smoke on the food with one filling.

For hot smoking I had to add a supplemental burner on the inside. This works great for drying the sausage to form the pellicle and then I fire up the smoke box and it will last a day.

Beautiful smokehouse.

- Butterbean

- Moderator

- Posts:1955

- Joined:Mon Mar 05, 2012 04:10

- Location:South Georgia

I think we are about the same. I was hoping mine would do like my other smoker and allow me to adjust the dampers to control the heat but no matter how big the fire it still just wouldn't budge. The other smoker is about seven feet from the firebox and I can get it up to 350 or so if I won't or turn it down for cold smoking. I think the reason for the difference has to do with the size of the smoke channel and the resulting draft.

As you are seeing, there is a lot of physics going on here and its way above my head. But while I really didn't want to have to have a supplemental heat system inside the house I am now glad I do because this really helps me during my process because rather than hanging the sausages in the air to dry before putting them in the smoke I can just hang them in the smoker with the gas heat to dry and then I can fire up the smokebox when they are ready to take smoke.

You might want to think on these lines a little because my other smoker doesn't have any gas heat and it is sometimes requires a bit of time to get all the moisture out of the box before I can put meat in it. Don't know how your moisture is in Texas but here it is something worth considering.

The other good thing I see with this new one over the old one is it will not get out of hand with the temp. I am really amazed at how long the box will lay smoke with just one fill up. My other one - with the exception of cold smoke - needs a couple of sticks every hour.

Not telling you what to do, just passing along what I've seen. But you are right, if it don't work like you intend you can always back it up some. Good luck with it and I'll be interested to see how it works out.

I gotta say its a beauty though.

As you are seeing, there is a lot of physics going on here and its way above my head. But while I really didn't want to have to have a supplemental heat system inside the house I am now glad I do because this really helps me during my process because rather than hanging the sausages in the air to dry before putting them in the smoke I can just hang them in the smoker with the gas heat to dry and then I can fire up the smokebox when they are ready to take smoke.

You might want to think on these lines a little because my other smoker doesn't have any gas heat and it is sometimes requires a bit of time to get all the moisture out of the box before I can put meat in it. Don't know how your moisture is in Texas but here it is something worth considering.

The other good thing I see with this new one over the old one is it will not get out of hand with the temp. I am really amazed at how long the box will lay smoke with just one fill up. My other one - with the exception of cold smoke - needs a couple of sticks every hour.

Not telling you what to do, just passing along what I've seen. But you are right, if it don't work like you intend you can always back it up some. Good luck with it and I'll be interested to see how it works out.

I gotta say its a beauty though.

I'm pretty happy with how things are turning out...and I kind of think it is a beauty tooButterbean wrote:I think we are about the same. I was hoping mine would do like my other smoker and allow me to adjust the dampers to control the heat but no matter how big the fire it still just wouldn't budge. The other smoker is about seven feet from the firebox and I can get it up to 350 or so if I won't or turn it down for cold smoking. I think the reason for the difference has to do with the size of the smoke channel and the resulting draft.

As you are seeing, there is a lot of physics going on here and its way above my head. But while I really didn't want to have to have a supplemental heat system inside the house I am now glad I do because this really helps me during my process because rather than hanging the sausages in the air to dry before putting them in the smoke I can just hang them in the smoker with the gas heat to dry and then I can fire up the smokebox when they are ready to take smoke.

You might want to think on these lines a little because my other smoker doesn't have any gas heat and it is sometimes requires a bit of time to get all the moisture out of the box before I can put meat in it. Don't know how your moisture is in Texas but here it is something worth considering.

The other good thing I see with this new one over the old one is it will not get out of hand with the temp. I am really amazed at how long the box will lay smoke with just one fill up. My other one - with the exception of cold smoke - needs a couple of sticks every hour.

Not telling you what to do, just passing along what I've seen. But you are right, if it don't work like you intend you can always back it up some. Good luck with it and I'll be interested to see how it works out.

I gotta say its a beauty though.

Regarding moisture....we don't have much in this part of TX....we'll see how it works out. What kind of humidity do you have to get down to in order to form a pellicle on your sausage?

It's encouraging that you can get your other smokehouse up to 350F...I'm really hoping to get this one just hot enough for sausage which is 170F from what I understand. Do you have any pictures of your other smoker?

TD

- Chuckwagon

- Veteran

- Posts:4494

- Joined:Tue Apr 06, 2010 04:51

- Location:Rocky Mountains

Beautiful craftsmanship! Those welds are smooth as a baby's bum! What kind of stick are you using? Sort of reminds me of the old DC 6010 with a rag flux. Smelled good when it burned! Great work TD.

Best Wishes,

Chuckwagon

Best Wishes,

Chuckwagon

If it looks like a duck, walks like a duck, and quacks like a duck, it probably needs more time on the grill!

I'm going to make sure it works first before I do anything...don't want to paint it if I've got to throw it in the junk iron heap! If it works good, I'll use a product called Ospho (maybe the same as "phosphatig" it?) and then paint over that with a brush and some good paint.ssorllih wrote:Nice work! Going to phosphate it or just paint it.

Travis

Thanks....but don't study the welding too hard! I see what some professional welders can do and it makes me feel like I'm simply playing around. Used 6011's on this.....Chuckwagon wrote:Beautiful craftsmanship! Those welds are smooth as a baby's bum! What kind of stick are you using? Sort of reminds me of the old DC 6010 with a rag flux. Smelled good when it burned! Great work TD.

Best Wishes,

Chuckwagon