Sooner or later it would happen- - I need a 3/8" stuffer tube for my new 5 lb. Grizzly stuffer. So, what to do? All attempts to find a 3/8" stuffer tube for my new stuffer failed. So I did what any other ambitious but cheap forum member would do.

"AHA!" sez I, with a swish of my superhero cape that I learned by watching the paso doble on "Dancing With The Stars." Bounding down the stairs (tripping once or twice on the cape before discarding it), I announced to all within earshot, "To the Duck-Cave! To the hardware store, forthwith! Awaaaaay!"

"Better make it fifth-with, Mister Super Hero," replied Beloved Spouse. "Don`t forget the grocery list."

Fortunately, I have a favorite hardware store which adjoins a grocery store, kinda-sorta nearby. It`s one of those country hardware stores with an ancient owner whose great granddaddy always bought two items when ordering, so he`d have a spare. Such refuges form the backbone of America and make it great (with application of a little elbow grease). The last ploughshares hammered out of swords are stocked there, along with every fitting you could ever desire. ...plus pork at a dollar a pound if you hit `em at the right time of the week.

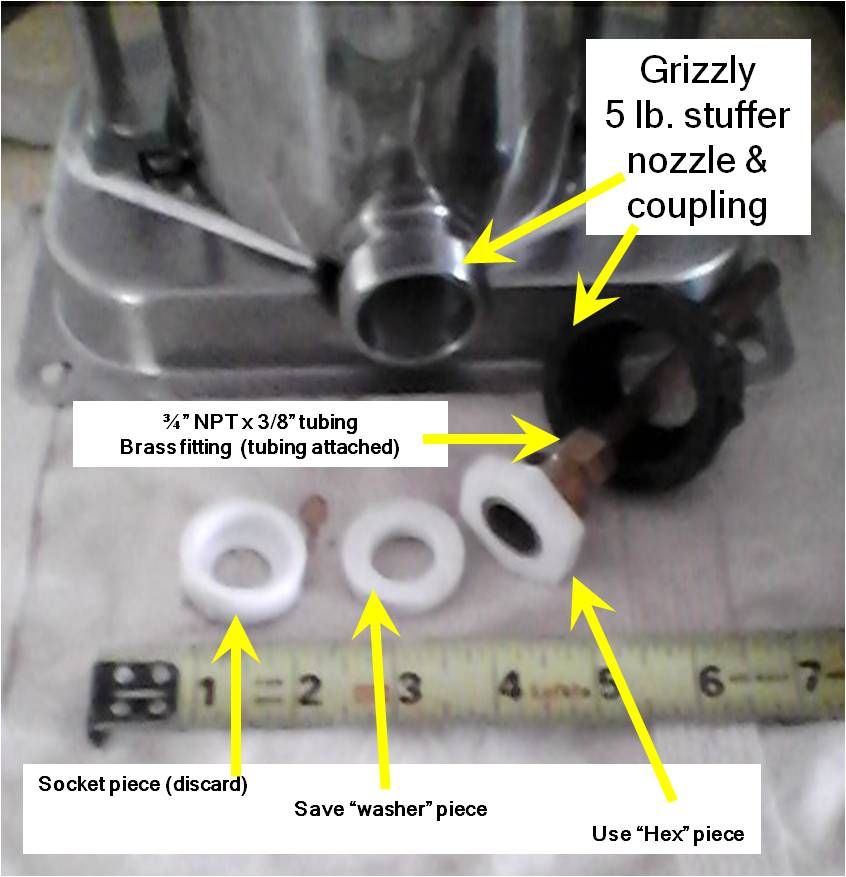

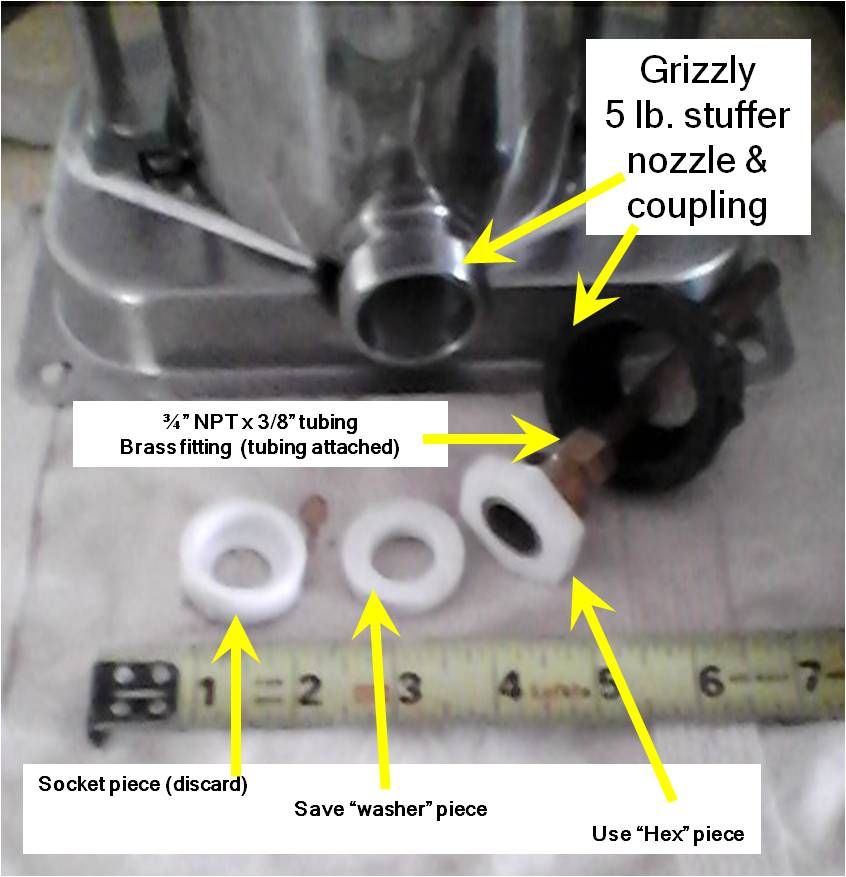

A dollar-nineteen later, I came home with a PVC coupling measuring 1" socket -x- 3/4" pipe thread, which would fit inside the 1-1/4" threaded opening and cap on my five-pound Grizzly stuffer after a little surgery.

Into it, I can screw the 1/2" brass coupling to 3/8" copper tubing compression fitting that I use on my "Russ-N-Ross Ramrod" stuffer (see elsewhere in the forum threads).

Back to the Duck Cave. Shedding groceries along the way. I clutched my prize in one hand and the Grizzly in the other.

You`ll note a couple of things from the picture. One, the coupling has a hexagonal edge which won`t quite fit down into the Grizzly coupling. Two, the new coupling is way too long. Thus the surgery.

I made two cuts with a hacksaw. By mounting the coupling in a vise, about two thirds of the way down, I used the steel jaws as a miter box, and cut off a fairly level section, removing the socket portion.

Next, I raised the PVC coupling in the vise, clamping it so the jaws acted like a miter box again, and cut flush to the molded hexagonal section. This removed a round, threaded-on-the-inside, section about 5/16ths long. This I sanded a bit to smooth out the cut marks.

The result is a threaded washer which will fit within the Grizzly`s coupling, which you can trap between the coupling and the nozzle, into which you can screw the brass/copper fitting and tubing. Depending upon your skill with a hack saw and sand paper, you can get a pretty good seal. If, like me, your cuts aren`t quite parallel, sand until you can make them more parallel. You could probably fit in a 1-1/4" diameter O-ring, but there isn`t quite enough thread left on the nozzle to accommodate it.

The second solution, and I think the better of the two, is to take the last piece with the molded-on hex shape, sand the points of the hex just enough to allow the piece to fit into the Grizzly `s coupling (clearing the threads), and sand the cut side to smooth out the cut marks. You had a much better chance of aligning the two faces on this particular piece, so it shouldn`t take too much sanding.

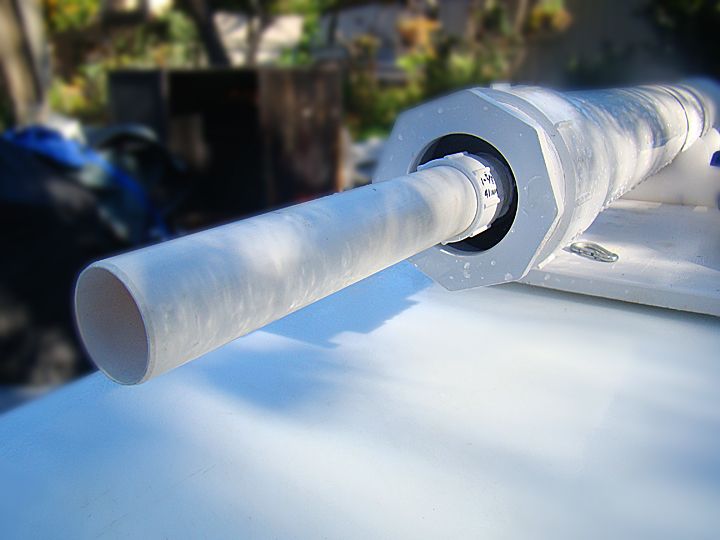

Slip your new adapter into the Grizzly`s coupling, screw the brass/copper piece in, then snug the Grizzly coupling onto the threaded nozzle. It should go on smoothly, yet take up enough thread that you won`t have a leak.

And there you have it- - brute force and ignorance triumph again! Now you can stuff those dinky little sheep casings and make snack stix and kabanosy to your heart`s content.